Valeo in Latin means “I am strong, I am worth.” And that’s what we set out to do, create a product of true strength and worth to protect the devices we rely on and can’t afford to lose.

I spent 7 years of my early career working at Apple, traveling the US and parts or Europe logging over a million miles in the air. During that time, I went through countless laptop sleeves and cases, replacing one after the other with different sizes and models to fit my newest device. A new laptop inevitably required a new case or sleeve. None of them truly protected my devices and over that time, I damaged the most important piece of technology I relied on for everything.

The next 7 years of my career were spent building a creative agency in Portland, Oregon. Unfortunately, or fortunately, depending on how you look at it, a part of my life remained clear across the continental US in Florida. My two children, from a previous marriage, still live in Florida, and since 2009, I have flown coast to coast at least once a month, every month, to be with them. I had to become an entrepreneur and build a company that could sustain my need to live a bi-coastal life. And on those trips to Florida, I had to continue running my business and the technology I carried with me, became even more important than ever. Running a startup is a 24/7 affair, and it became clear to me, that I couldn’t afford to have my MacBook Pro damaged.

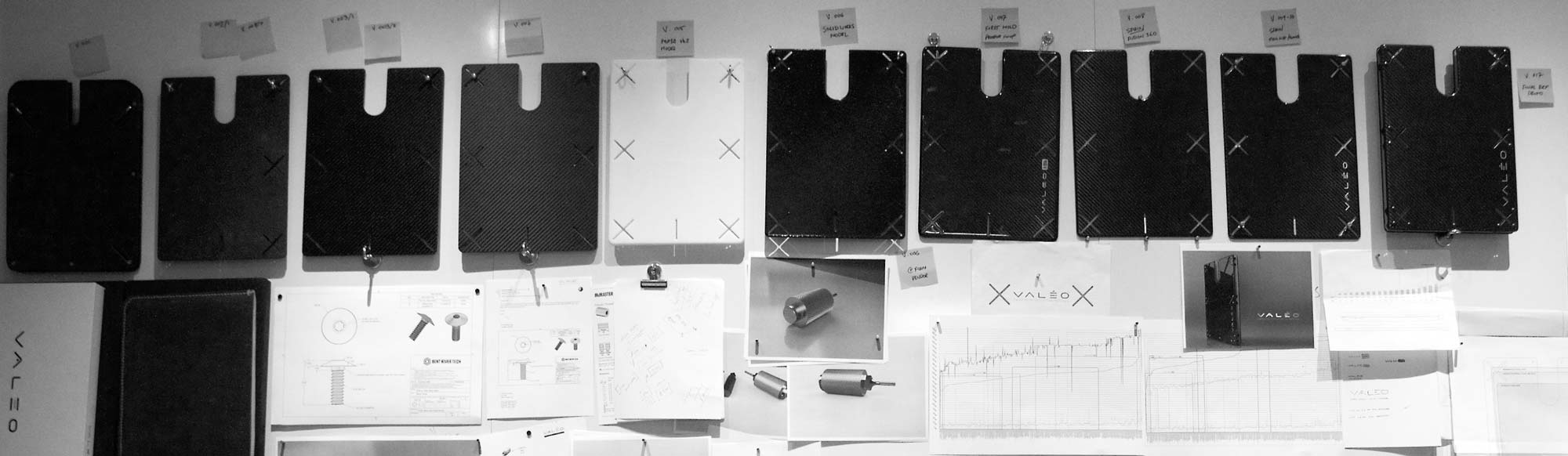

Valeo was born out of this need – because there wasn’t a single laptop sleeve or case that really worked. I needed something to really protect my laptop, which got thinner and more breakable with every new model. Just over two years ago – I guess you could call it my “a-ha!” moment – I recall bending over to tie my shoe laces at the airport and feeling the pressure on my brand new 15″ MacBook Pro against my arched back. The neoprene sleeve I was using did nothing to protect it, neither did my backpack which had a specifically designed “padded laptop pouch”. It was at the moment that I had the idea to cut down a sheet of aluminum to reinforce my backpack. As it turns out, an 11″x15″ sheet of 1/4″ thick aluminum was a lot heavier than I imagined, which ultimately led me research carbon fiber. There’s a reason you’ll find carbon fiber in everything from airplanes to sports cars. There just isn’t another material like it. There was nothing else out there as strong and light weight as the 2mm sheets of carbon fiber that made up the first crude Valeo prototype. This brutally dremmel’d case, is Valeo prototype #1.

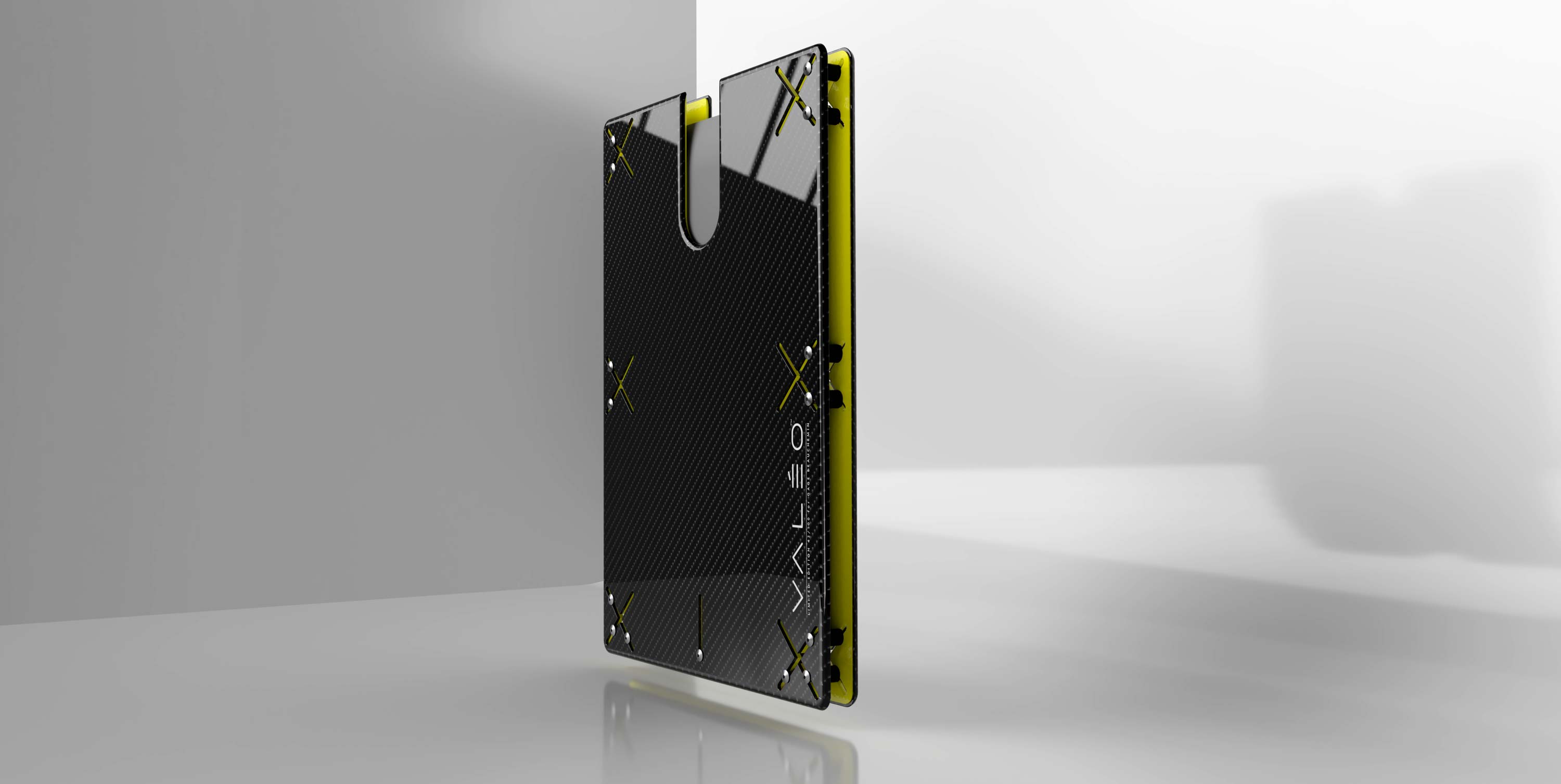

Not long after this, I had my second “a-ha!” moment, when I realized the positions I had drilled for the bumpers, were not quite right. Instead of drilling another set of holes, I came up the idea to create channels for each set of screws and bumpers to be able to freely adjust them. These channels eventually became the patent pending X’s you see on every Valeo Case.

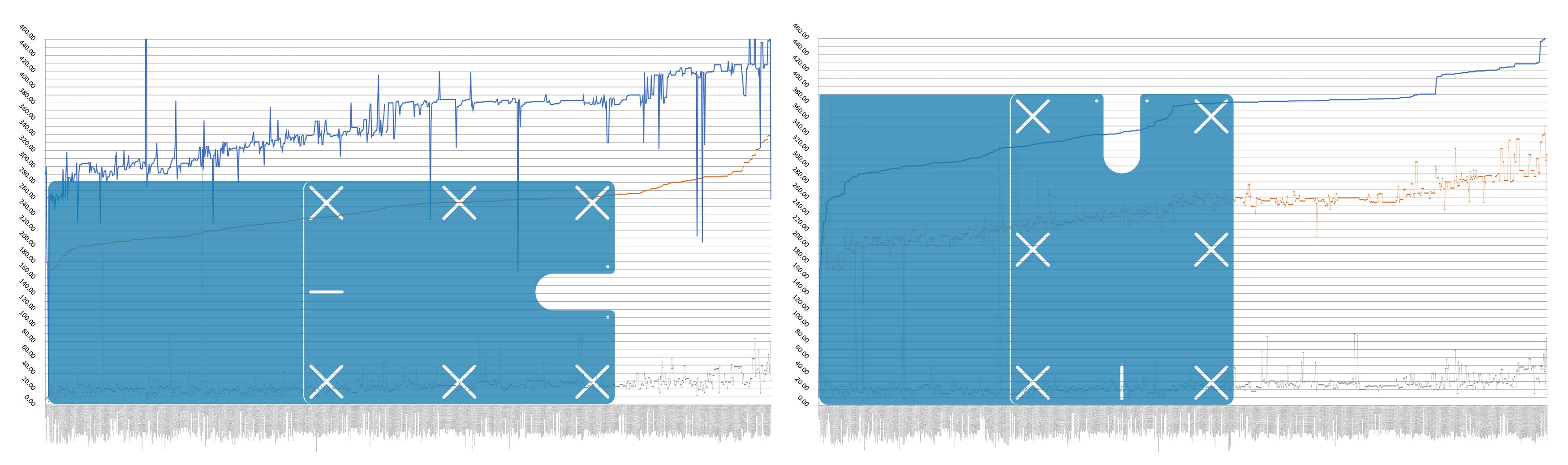

At that point I had strength and the mechanics of holding two carbon fiber sheets together to create an ultra strong and lightweight case. The X’s also solved another design challenge – how to make this as much of a one-size-fits-all product as possible. I needed it to work with as many devices as possible and I wanted it to last through multiple device upgrades. I had sized the first version to fit my MacBook Pro 15″ perfectly. I did this by simply plotting an image of the laptop on the case drawings. The question was, how many other laptops and tablets would this size case work with.

I needed to figure out the ideal size to make this first version to cater to as wide a swath of devices as possible and still keep it compact to also fit into as many backpacks as possible. I researched the dimensions of almost 100 popular notebooks and tablets on the market and during this process, discovered Intel’s PC specs website. Intel publishes the specs of every laptop and tablet device on the market with an Intel chip inside. This was as close to the perfect sample set I was going to get. After some data-mining (thank you Intel), I plotted out the length, width and hight of over 1200 laptops and tablet PCs. Then, sorting them by first width then hight, I superimposed my first Valeo model. Turns out, my original dimensions allowed the case to fit roughly 60% of all shipping laptops and tablets on the market. That was eye-opening. But I also learned, that if made the case just 10mm taller, it would fit roughly 75% of all laptops and tablets currently shipping. If the same Valeo case could work for 75% of laptop and tablet users in the world, I was happy with that.

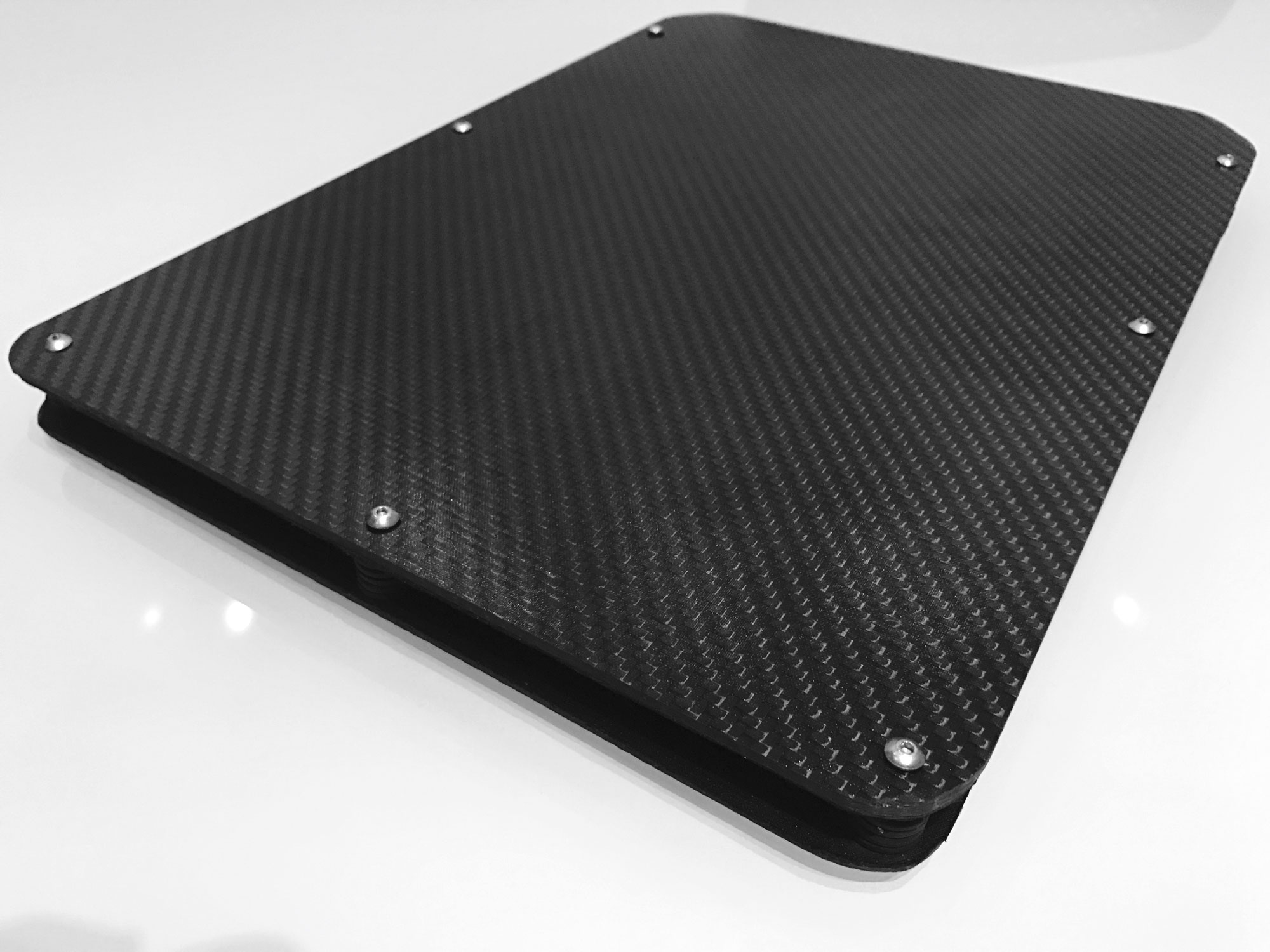

What came next, over the course of two years, was an exhaustive search for the right bumpers, foams, screws, carbon fiber manufacturers, suppliers, machine shops… the list goes on. In the end, much like the original need to create something completely custom because nothing out there was good enough, the screws, bumpers, carbon fiber panels, even the Valeo Hex tool – all of it had to be custom designed and manufactured. None of Valeo is off the shelf, because nothing off the shelf was good enough.

It took a year to get to the perfect screw design. It took almost a year working with a local composites firm to get the next three prototypes out and another 8 months of working with our composites supplier in Spain to get the beveled edges, finish and repeatable performance of our carbon fiber panels.

After two years of design and development, the end result is what I truly believe to be, the last laptop case, you’ll ever need.